The current McKinsey Quarterly feature’s Andy Grove’s editorial, An electric plan for energy resilience. An excerpt:

We believe the United States should consider accelerating this movement by creating an industry of after-market retrofitters. What problems’”technical and economic’”would need to be solved in order to do that? With the help of a team of second-year graduate students in our Bass seminar at the Stanford Business School, we examined this question in the context of a proposed pilot program, whose aim would be to retrofit one million vehicles in three years. We felt that such a project would represent what in game theory is referred to as the ‘minimum winning game’: a significant step toward a long-term strategic objective (see sidebar, ‘Inside Andy’s real-world seminar’).

We estimate the price tag of such a pilot project to be around $10 billion, owing to the present high cost of batteries, which are around $10,000 each. One might expect such costs to drop as volume increases, but because this program is accelerated by design, we have to assume that batteries will remain expensive. Assuming an average gas price of $3 per gallon, the payback period to the owner of a retrofitted vehicle is at least ten years, not a strong economic incentive. But the benefits of this program’”testing and validating a key approach to energy resilience’”accrue to the well-being of the United States at large. As the general population is the predominant beneficiary, economic assistance flowing from everyone to vehicle owners, in the form of tax incentives, is justified.

There are different approaches to retrofitting vehicles. We favor GM’s Volt design, in which the car is directly driven by an electric motor. The vehicle’s existing gasoline engine is replaced by a smaller one, whose sole purpose is to generate electricity and recharge the battery. To simplify the retrofitting task, we would limit the scope of the program to six to ten Chevrolet, Ford, and Dodge models, selected on the basis of two criteria: low fuel efficiency and large numbers of vehicles on the road. Most of these vehicles would be SUVs, pick-ups, and vans.

There’s some wisdom in this proposal, particularly in the recognition that achieving an alt fuel vehicle transformation takes more than a few inventions; it requires changes in infrastructure, marketing, and a variety of other domains, each with bugs to be worked out:

Others wondered why we should bother retrofitting a million cars if that would deal only with a fraction of a percent of the existing cars. That’s one way to look at it. Another, which was the view our students took, is that it is important to strive to do enough conversions that we can encounter all the unknown unknowns, which in my experience characterize every new product or technology as it gets scaled into volume. Should it be 5 million? Should it only be 500,000? We picked a million as a number that is big enough to stress retrofitting capability, battery production capability, manufacturing issues and marketing issues. We described our aim as the ‘minimum winning game’ that would give us a platform from which we could scale further.

However, the retrofit idea strikes me as fundamentally flawed. Targeting low efficiency SUVs, pick-ups, and vans puts batteries exactly where they’d be least effective. If most such vehicles weren’t overweight, un-aerodynamic, saddled with lossy AWD, and bloated with power-hungry accessories, they’d already get decent fuel economy. Adding batteries to them is going to result in some combination of high cost, short range, and poor performance. That sounds like a sure way to poison the public perception of plug in electric vehicles.

RMI has been arguing for years that a coordinated set of chassis innovations could make powertrains with high cost-per-watt, like fuel cells, attractive. It’s no accident that that the only really successful hybrid vehicle (the Prius, responsible for over half of 2007 and 2008 hybrid sales) was designed from scratch. It gets its breakthrough mileage/performance combination from much more than a battery and motor. Lightweight materials, aerodynamics, low rolling resistance tires, and other innovations are also key.

I think Grove and his students are falling for a common fantasy: that technology will step up and allow us to drive exactly as we now do, fossil-free. I personally doubt that will happen. Arnold will probably be one of only a few to ever drive a hydrogen Hummer. The rest of us will have to recognize that if alt fuel vehicles are to accomplish anything really meaningful from an energy standpoint, they’ll be different, as will our land use, commuting, and travel habits.

With that in mind, we should be focusing on creating the new stuff, not fixing the old. That might mean the Chevy Volt, but it might also mean rail or telecommuting. Rather than setting up programs to achieve narrow goals, I’d rather see broad, credible signals (e.g., prices at the pump reflecting environmental and security values) guide the evolution of the new from the bottom up.

Are you familiar with Better Place?

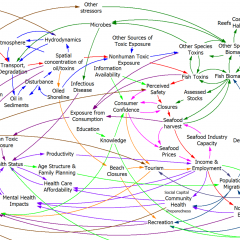

John Sterman has given a terrific lecture at MIT Sloan on the issue around the electric car (http://www.systemdynamics.org/wiki/index.php/Resources#Webcasts – Why Do Bad Things Happen to Good Technologies?)

Stripping it up from the wrong side and with not enough effort (especially around the “side-effects” that are not obvious in the beginning):-(

It takes thinking, prototyping (of the process) and reflecting. All could be done in SD modeling together with real life action research.

Don’t let us see the “disaster” in not achieving the necessary goals while the big shots are already working overtime – let’s follow in do the work collaboratively;-)

Cheers and a Happy New Year with all that is wishable

Ralf

Betterplace – yes, I’d seen the Wired article on Shai Agassi a few months ago. It seems like they’re going after sensible things, like charging infrastructure. I’ve seen some criticism of the battery-swap logistics, but that seems like the least essential leg of their plan.